|

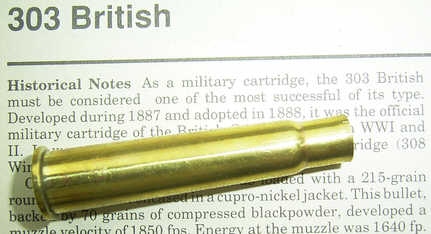

Over the years I've tried most of the methods for reforming common available rifle brass into workable .410 cases. While .444 Marlin has the correct base diameter, it is neither plentiful nor cheap, and its rim diameter is too small so that it often falls off the extractor. Brass for the .303 British is both plentiful and cheap here in the US, and can be easily reformed to make suitable, if somewhat short .410 cases which permit normal 2-1/2", 1/2 oz. shot charges, buck & ball or buckshot/roundball loads. I recommend starting with either new or once-fired commercial brass. Military cases have a harder anneal and are more prone to mouth splits unless you reanneal them first. Best is if you have an RCBS .35 Brown-Whelan expander die. This has a long gentle taper from .30 caliber to .40 intended to expand .30-'06 cases to .40 in one pass, which is necessary to form a new shoulder farther forward than the original, to headspace them for wildcat fire-forming. If you have one of these, inside neck lube your brass with lanolin or lithium wheel bearing grease and gently neck up your cases from .30 to .375 in about 3 separate stages. If the mouths split, then you need to mouth anneal cases before starting and/or do the reforming process in more gradual stages. Another expedient method is to buy Lee .38-56 Winchester dies, which are relatively inexpensive, being made for the Cowboy action shooters. First remove the decapping stem and either lathe turn or taper the expander plug portion with a file in the drill press, to produce a gradual taper which will enter the .303 case mouth easily and enlarge to the full .375" diameter over a distance of about 3/4", leaving only a slight cylindrical portion at the top. This works like the Brown-Whelan expander, but makes .375 Flanged cases instead. Prime and load these with a fire-forming charge of 12 to 13 grs. of #2400, with a ball of newspaper wadding pushed firmly onto the power charge with a wooden dowel, then fill the case with any available small shot up to the mouth and place a 000 buckshot or cast .375 round ball on top. Crimping is done using the .38-56 seater die, but first you need to substutute insert a Lyman or RCBS lubricator-sizer top punch for a blunt roundnosed .45 bullet for the seater plug in the die. Tighten the seater plug to bottom the shoulder of the cast bullet top punch against the interior shoulder of the .38-56 seater die. This results in a nearly flush seated, nicely radiussed heavy crimp which results in perfect fire-forming. The rounds look almost factory quality. Since the .303 brass is a bit small at the base, before fire forming take two wraps of ordinary paper masking tape around the base to take up the excess space, and to center the fire-forming round in the chamber. This ensures that the case body will expand evenly all the way around, instead of possibly leaning off-center on just one side. Once the case has been fired, you can remove the tape, because the expanded body will center itself in future firings. Reload fire-formed cases using .444 Marlin dies with the .303 shell holder. After fire-forming you can use Ox Yoke Originals .44-45 felt wads sold for cap & ball revolvers. Be sure to change the roundnosed cast bullet top punch over to your .444 seater to use there after you have fire formed the cases. The buck&ball loads are quite effective against coyotes and similar varmints. The 2.25" long case will accept FOUR 000 buck or .375 round balls over an Ox Yoke wad and 13 grains of #2400, crimping the last one in the end. This makes an authoritative and deadly load which much greater killing power than the anemic .410 slug. Warning: |